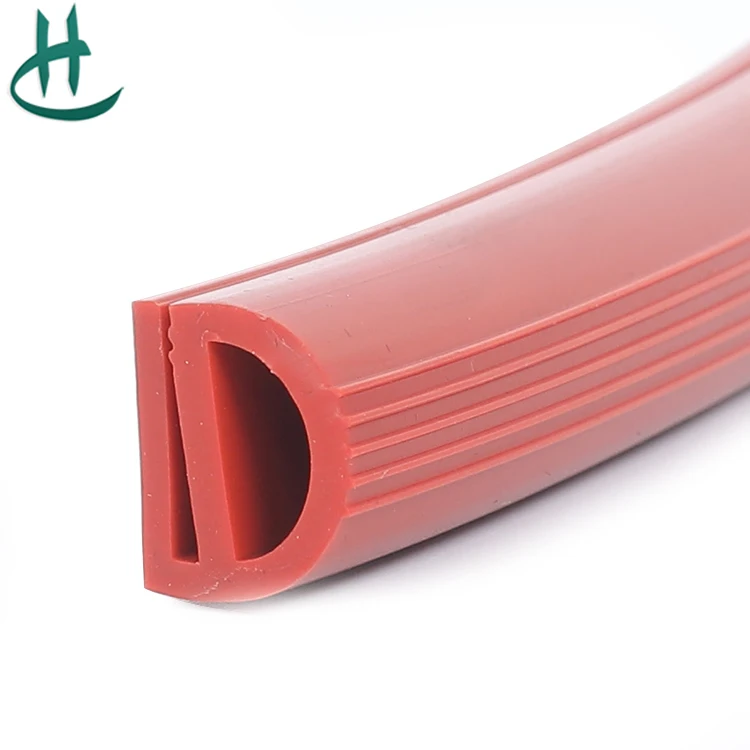

Using OEM parts, such as window sponge seals, ensures that the product adheres to the original specifications set by the manufacturer. This is critical because non-OEM products may not offer the same level of quality, durability, or fit. OEM seals are engineered to meet stringent industry standards, which means they are tested for performance, reliability, and longevity. When manufacturers choose OEM window sponge seals, they are investing in quality assurance that can enhance their products’ overall lifespan and effectiveness.

Home

Home

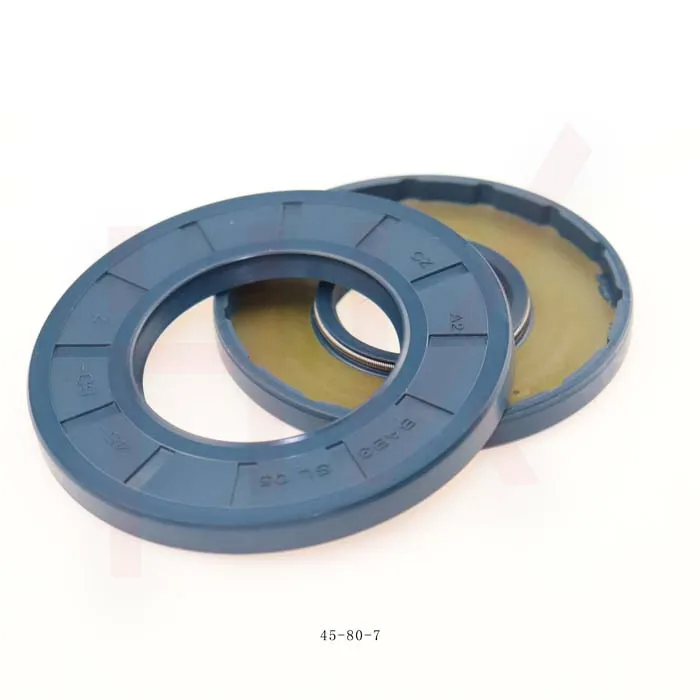

Additionally, leaking fluid can also lead to contamination of the surrounding environment, posing a risk to both the equipment and the safety of operators Additionally, leaking fluid can also lead to contamination of the surrounding environment, posing a risk to both the equipment and the safety of operators

Additionally, leaking fluid can also lead to contamination of the surrounding environment, posing a risk to both the equipment and the safety of operators Additionally, leaking fluid can also lead to contamination of the surrounding environment, posing a risk to both the equipment and the safety of operators The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies

The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies The seals' motifs provide a unique insight into the beliefs, myths, and daily life of these ancient societies It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages

It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages A skilled technician must ensure that each seal is correctly positioned and not over-compressed during assembly, as this could compromise its integrity A skilled technician must ensure that each seal is correctly positioned and not over-compressed during assembly, as this could compromise its integrity

A skilled technician must ensure that each seal is correctly positioned and not over-compressed during assembly, as this could compromise its integrity A skilled technician must ensure that each seal is correctly positioned and not over-compressed during assembly, as this could compromise its integrity